The Cost of Wood Pallets: Understanding the Financial Implications for Businesses

Introduction

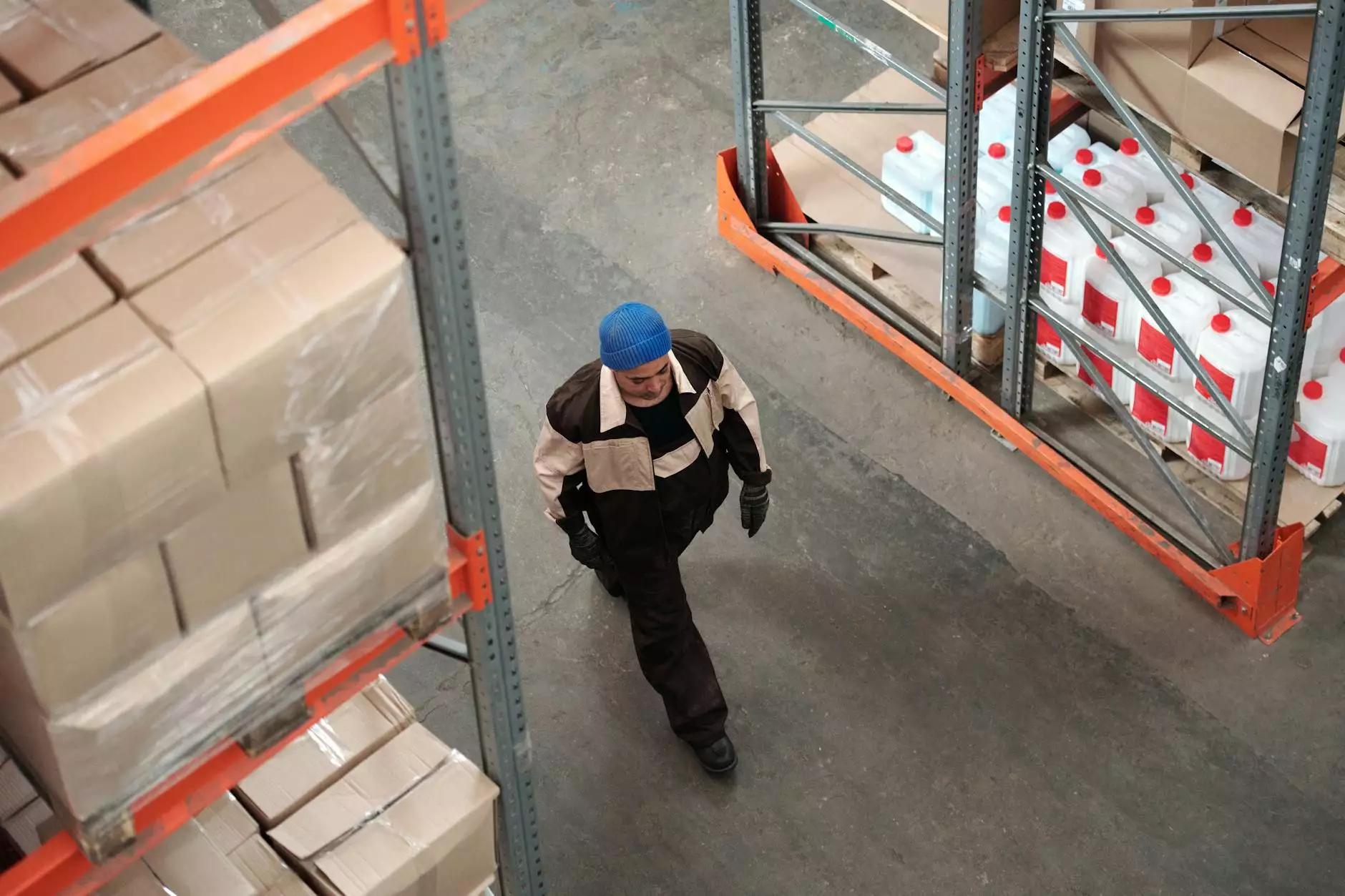

When it comes to managing logistics and supply chains, wood pallets serve as an essential component for transporting goods. The cost of wood pallets can significantly affect the overall operation expenses of businesses, especially those in manufacturing, warehousing, and distribution. Understanding these costs can empower timber merchants and wood suppliers to make informed decisions.

What Influences the Cost of Wood Pallets?

The price of wood pallets is not a straightforward figure; instead, it is influenced by a variety of factors. Here are the primary elements that play a crucial role:

- Material Quality: Higher quality wood typically results in higher prices. Pallets made from hardwoods like oak and maple are usually more expensive than those made from softwoods such as pine.

- Size and Design: Standard pallet sizes generally cost less compared to custom-designed pallets. A custom size may involve additional costs for materials and labor.

- Production Processes: The method of pallet manufacturing can affect pricing. Pallets made using advanced equipment may incur higher costs than those produced manually due to labor and operational expenses.

- Market Demand: Fluctuations in market demand for wood pallets, influenced by seasonal changes and economic conditions, affect pricing.

- Availability of Resources: Local timber availability can have a major impact on costs. Regions with abundant wood supply may offer lower prices.

- Transportation Costs: The location from which the pallets are sourced also plays a significant role. Higher transportation costs can lead to increased prices.

- Recycled vs. New Pallets: Choosing to purchase refurbished or recycled pallets can lead to considerable savings compared to new pallets.

Understanding Different Types of Wood Pallets

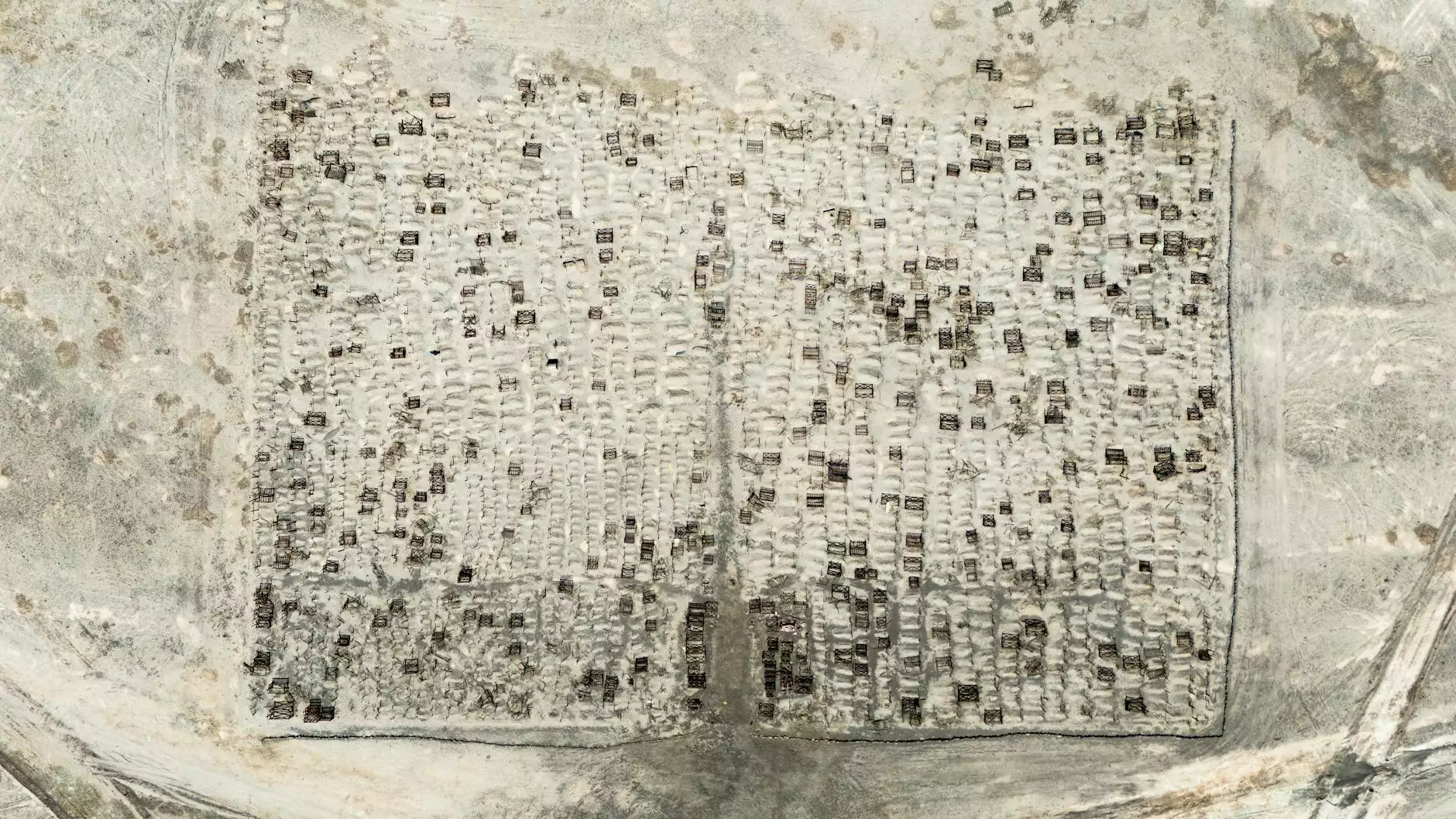

Different types of wood pallets are available in the market, and each type has its own cost structure. Here are some common types:

- Standard Pallets: The most commonly used pallets, often measuring 48” x 40”.

- Custom Pallets: Tailored to specific dimensions or designs as per customer requirements, thus potentially increasing costs.

- Double-Deck Pallets: More robust but higher in price; typically used for heavy loads.

- Export Pallets: Specifically designed for shipping goods across international borders; may comply with certain regulations leading to an increase in cost.

- Plywood Pallets: A cost-efficient alternative; the price can vary depending on the thickness and quality of plywood used.

Comparing New and Used Wooden Pallets

An essential consideration for businesses is whether to select new or used wooden pallets. Each option has its benefits and costs:

New Wooden Pallets

Advantages:

- Guaranteed quality and durability.

- Can't be rejected on the basis of condition.

- Customizable to your specifications.

Disadvantages:

- Higher initial investment.

- Longer lead time for production.

Used Wooden Pallets

Advantages:

- Cost-effective option with significant savings.

- Quick availability and often found locally.

Disadvantages:

- Variable quality; potential for damage.

- Limited availability of specific sizes or designs.

Estimating the Cost of Wooden Pallets

To accurately gauge the cost of wood pallets, businesses should consider not only the initial purchasing price but also the total cost of ownership. This includes:

- Initial Purchase Price: The upfront cost incurred when acquiring the pallets.

- Maintenance Cost: Includes repairs or replacements needed for damaged pallets over time.

- Transport Cost: The expenses associated with transporting pallets to your facility.

- Storage Cost: Costs linked to the space required for storing wood pallets.

- Replacement Cost: Anticipating the frequency with which pallets will need to be replaced, thereby affecting long-term budgets.

By analyzing these categories, you can ensure that your business can make informed financial decisions surrounding pallet usage.

Where to Purchase Wood Pallets

Choosing the right supplier is crucial for obtaining wood pallets that meet your needs. Here are some suggestions on where to start:

- Timber Merchants: Often carry a wide variety of pallets and can assist with custom orders.

- Wood Suppliers: Look for reputable suppliers with established quality control standards.

- Online Marketplaces: Websites like Craigslist or local classifieds may have listings for used pallets, often at a reduced cost.

- Pallet Manufacturers: Directly sourcing from manufacturers can often yield competitive pricing, especially for bulk orders.

Innovations in Wood Pallet Design

Innovation in the design and manufacturing of wooden pallets has led to better efficiency and cost-effectiveness. Some recent developments include:

- Eco-Friendly Pallets: Made from sustainably sourced wood or alternative materials, catering to environmentally conscious businesses.

- Smart Pallets: Equipped with RFID or QR codes for inventory management, enhancing tracking capabilities.

- Stackable Designs: Innovations in design have led to pallets that stack more efficiently, saving space and optimizing transport costs.

Conclusion

Understanding the cost of wood pallets is crucial for businesses relying on effective logistics and transportation solutions. From the quality of materials to the specific use case and design requirements, several factors influence pricing. By being informed about these aspects, businesses can make strategic purchasing decisions that enhance operational efficiency and cost-effectiveness. As timber merchants and wood suppliers, recognizing market trends, innovations, and best practices in sourcing can significantly impact the long-term success of your operations.

For more information about wood supply and timber merchandise, visit Stary Timbers.