The Ultimate Guide to Vakuumsack: Unlocking the Benefits for Your Business

In today's competitive market, every business is constantly in search of ways to improve efficiency and product quality. One effective solution that has gained prominence in various industries is the use of Vakuumsack, or vacuum bags. These versatile tools play an essential role in packaging, storage, and preservation. This article explores the myriad benefits of using Vakuumsack for your business, including the types available, their applications, and how they can enhance operational workflows.

Understanding Vakuumsack: What is It?

A Vakuumsack is a specialized packaging solution designed to remove air from the bag before sealing it. This process not only protects the contents from external elements but also extends the shelf life of food and other perishable items. By significantly reducing the air inside the packaging, vacuum sealing minimizes the oxidation of food, thus keeping it fresh for an extended period.

Why Choose Vakuumsack for Your Business?

- Enhanced Preservation: Vacuum sealing drastically reduces spoilage and waste. It locks in flavors, nutrients, and moisture, ensuring that products reach customers in optimal condition.

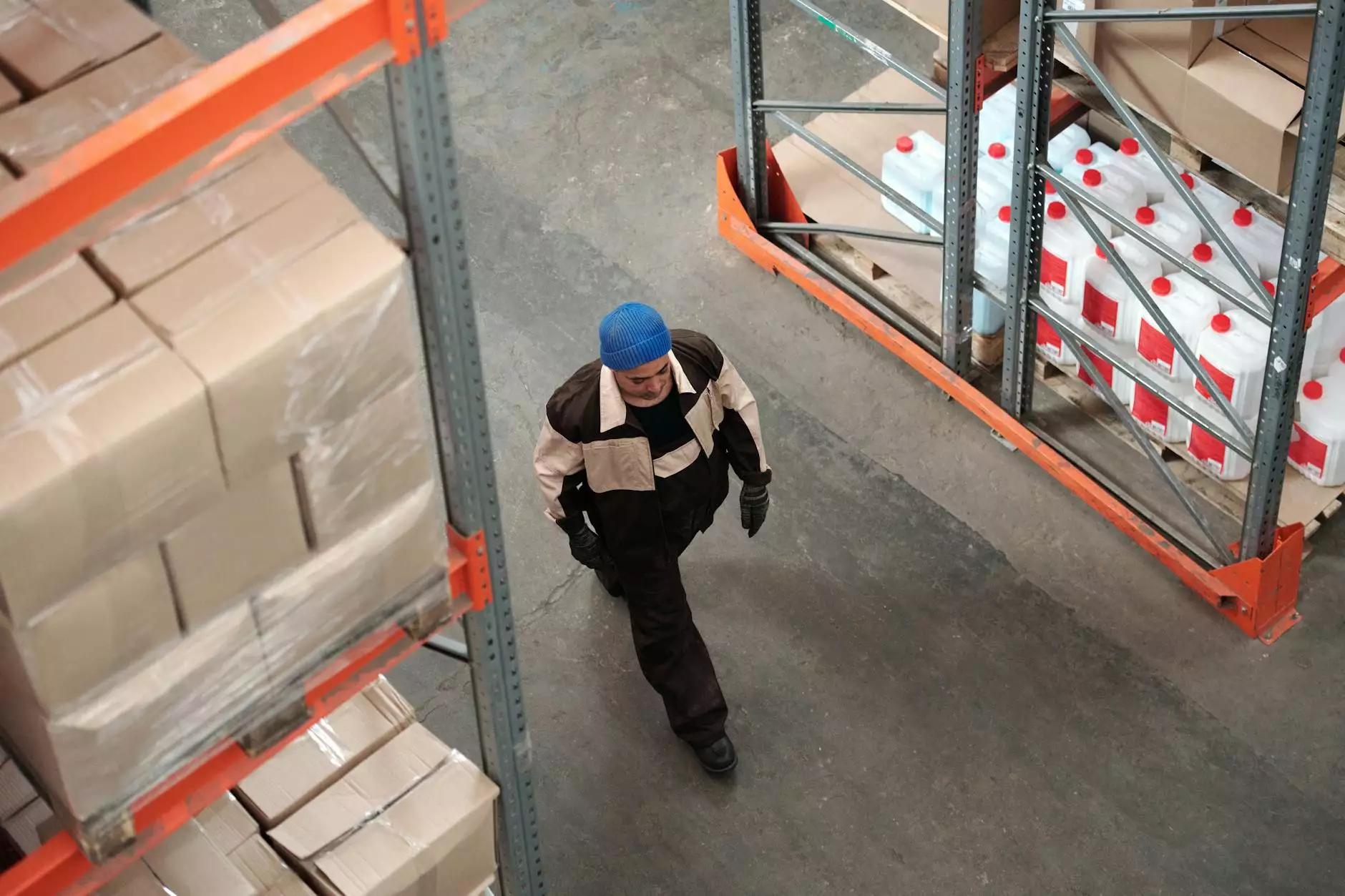

- Space Efficiency: Removing air creates less bulk, allowing for more efficient use of storage space in warehouses and retail locations.

- Versatility: Vakuumsack can be used across multiple sectors including food, pharmaceuticals, and electronics, making it a valuable tool for diverse businesses.

- Cost-Effective: By extending the shelf life of products, businesses can reduce losses and improve profitability.

Types of Vakuumsack: Finding the Right Fit for Your Needs

Different industries have varying requirements when it comes to packaging. Understanding the types of Vakuumsack available is crucial for optimizing your business operations:

1. Flat Vacuum Bags

Flat vacuum bags are one of the most common forms of Vakuumsack. They are ideal for packaging food items like meats, fish, and vegetables. The easy-to-use design allows for quick sealing, making it a great choice for high-volume operations.

2. Gusseted Vacuum Bags

These bags feature an expandable bottom that allows for more storage space. Gusseted bags are perfect for bulkier items, such as grains or larger cuts of meat, providing both protection and long-term preservation.

3. Heat-Sealable Vacuum Bags

For businesses that require extra durability, heat-sealable bags offer superior sealing capabilities. These bags can withstand higher temperatures and are often used in sous-vide cooking scenarios.

4. Specialty Vacuum Bags

Some businesses may require more specialized solutions, such as vacuum bags designed to resist punctures or those coated for additional moisture barrier properties. Understanding these differences can help tailor the right _vakuumsack_ for specific applications.

Applications of Vakuumsack Across Various Industries

The utilization of Vakuumsack spans numerous industries, each benefiting from the preservation and efficiency these vacuum bags offer:

Food Industry

In the food sector, vacuum packaging is essential for extending the shelf life of perishable goods. From meat producers to bakeries, effective packaging ensures that products remain fresh, reducing waste and increasing customer satisfaction.

Pharmaceutical Industry

In pharmaceuticals, maintaining the integrity and potency of medications is crucial. Using vacuum bags for packaging helps protect these sensitive products from moisture and contamination, ultimately ensuring their effectiveness upon delivery to patients.

Electronics and Equipment

Items such as circuit boards and other electronic components require protection from environmental factors. Vacuum packaging can safeguard these products from dust and moisture during transit and storage, ensuring they arrive in perfect condition.

Benefits of Using Vacuum Systems with Vakuumsack

The integration of a vacuum system with your Vakuumsack can significantly enhance your packaging process. Here are some advantages:

- Automation: Modern vacuum systems can automate the sealing process, saving time and labor costs while increasing output.

- Consistency: Automated systems provide uniform sealing, reducing the risk of human error and ensuring high-quality packaging.

- Temperature Control: Advanced vacuum systems can control sealing temperatures to match the specific requirements of different materials, ensuring optimal results.

Choosing the Right Vacuum System for Your Vakuumsack

Selecting an appropriate vacuum system to accompany your Vakuumsack is critical for maximizing your investment. Here are key factors to consider:

1. Volume Requirement

Assess your production needs. For high-volume operations, consider a commercial-grade vacuum system capable of handling increased throughput.

2. Type of Products

Different products may require specific sealing capabilities. Ensure the vacuum system is compatible with the types of bags and contents you plan to use.

3. Level of Automation

Evaluate whether you need a fully automated system or a semi-automated one. Completely automated systems are ideal for high-volume production, while semi-automated systems may suffice for smaller batches.

Common Mistakes to Avoid When Using Vakuumsack

While using Vakuumsack, businesses often encounter pitfalls that can undermine the benefits. Here are common mistakes to avoid:

- Incorrect Bag Size: Using bags that are too large or small can result in ineffective sealing. Always match the bag size to the contents.

- Poor Sealing Techniques: Ensure proper sealing techniques are used to prevent air from entering the bag after sealing.

- Overfilling Bags: Overstuffing bags can hinder the vacuum seal. It is essential to leave enough room for effective sealing and air removal.

Taking Care of Your Vakuumsack Equipment

Maintaining your vacuum packaging equipment is essential to ensure longevity and consistent performance. Here are some care tips:

Regular Cleaning

Consistently clean your vacuum machines and sealing elements to remove any food residues or debris. This practice not only maintains hygiene but also prevents cross-contamination.

Periodic Maintenance

Schedule routine maintenance checks for your vacuum sealing equipment to identify and resolve potential issues before they escalate.

Conclusion: The Future of Vakuumsack in Business

As businesses continue to seek innovative ways to preserve product quality and reduce waste, the role of Vakuumsack has become increasingly significant. With various types of vacuum bags and systems available, understanding your specific needs can lead to informed decisions that enhance operational efficiency and customer satisfaction.

By investing in high-quality vacuum bags and robust vacuum systems, businesses can protect their products, streamline operations, and ultimately boost their bottom line. Whether you're in the food industry, pharmaceuticals, or electronics, embracing the power of Vakuumsack is a step towards sustainable and profitable business practices.