The Essential Role of Engine Fuel Pumps in Diesel Engines

Engine fuel pumps are crucial components in the operation of diesel engines. They play a vital role in ensuring efficient fuel delivery, optimizing performance, and contributing to the overall longevity of the engine. In this extensive guide, we will delve into the intricacies of engine fuel pumps, their types, functionality, maintenance tips, and our recommendations for sourcing high-quality products from suppliers like client-diesel.com.

What is an Engine Fuel Pump?

An engine fuel pump is a device designed to transfer fuel from the tank to the engine at the correct pressure needed for optimal combustion. In a diesel engine, the fuel pump is especially important due to the unique properties of diesel fuel and the operational characteristics of diesel engines.

Types of Engine Fuel Pumps

There are primarily two types of engine fuel pumps used in diesel engines:

- Mechanical Fuel Pumps: These pumps are typically driven by the engine's camshaft and are commonly found in older diesel engines. They are reliable and straightforward in design.

- Electric Fuel Pumps: More prevalent in modern engines, electric fuel pumps are powered by the vehicle's electrical system. They are capable of providing higher pressure and can be more precisely controlled, enhancing efficiency and performance.

How Engine Fuel Pumps Work

The primary function of an engine fuel pump is to ensure that fuel flows from the tank to the engine in a controlled manner. The process involves several steps:

- Fuel Intake: The fuel pump draws fuel from the tank through a filter to remove impurities.

- Pressurization: After intake, the pump increases the fuel's pressure, which is necessary for optimal spray pattern and atomization in the engine's combustion chamber.

- Delivery to Engine: The pressurized fuel is then supplied to the injectors, where it mixes with air and combusts to produce power.

The Importance of Fuel Pressure

Maintaining the correct fuel pressure is essential for the performance of diesel engines. An engine fuel pump must deliver fuel at specific pressures to ensure efficient combustion. If the pressure is too low or too high, it can lead to a variety of operational issues, including:

- Poor fuel economy

- Increased emissions

- Rough engine performance

- Difficulty starting the engine

Signs of a Failing Engine Fuel Pump

Understanding when your engine fuel pump is failing is crucial for timely maintenance and repair. Here are some common signs of issues:

- Engine Stalling: If your engine stalls frequently, especially when idling, it may indicate a fuel delivery problem.

- Sputtering Engine: A sputtering engine can be a sign of fluctuating fuel pressure.

- Decreased Performance: Lack of power or sluggish acceleration can result from inadequate fuel supply.

- No Start: If your engine cranks but doesn’t start, it could mean the fuel pump isn’t delivering fuel.

Maintenance Tips for Engine Fuel Pumps

To ensure the longevity and effectiveness of your engine fuel pump, consider the following maintenance tips:

- Regular Fuel Filter Changes: Keep the fuel filters clean and replace them regularly to prevent debris from clogging the pump.

- Monitor Fuel Quality: Always use quality diesel fuel to avoid contaminants that can harm the pump.

- Check for Leaks: Regularly inspect the fuel system for leaks, which can lead to air entering the system and affecting pump performance.

- Listen for Noise: Unusual sounds from the fuel pump could be an early warning signal of a problem.

Choosing the Right Engine Fuel Pump

When selecting an engine fuel pump, it's important to consider factors such as:

- Vehicle Specifications: Ensure compatibility with your engine type and model.

- Manufacturer Reputation: Opt for trusted brands that are known for their quality and reliability.

- Pressure Requirements: Check for the required pressure specifications suitable for your diesel engine.

- Warranty and Support: Consider products that come with a warranty and reliable customer support.

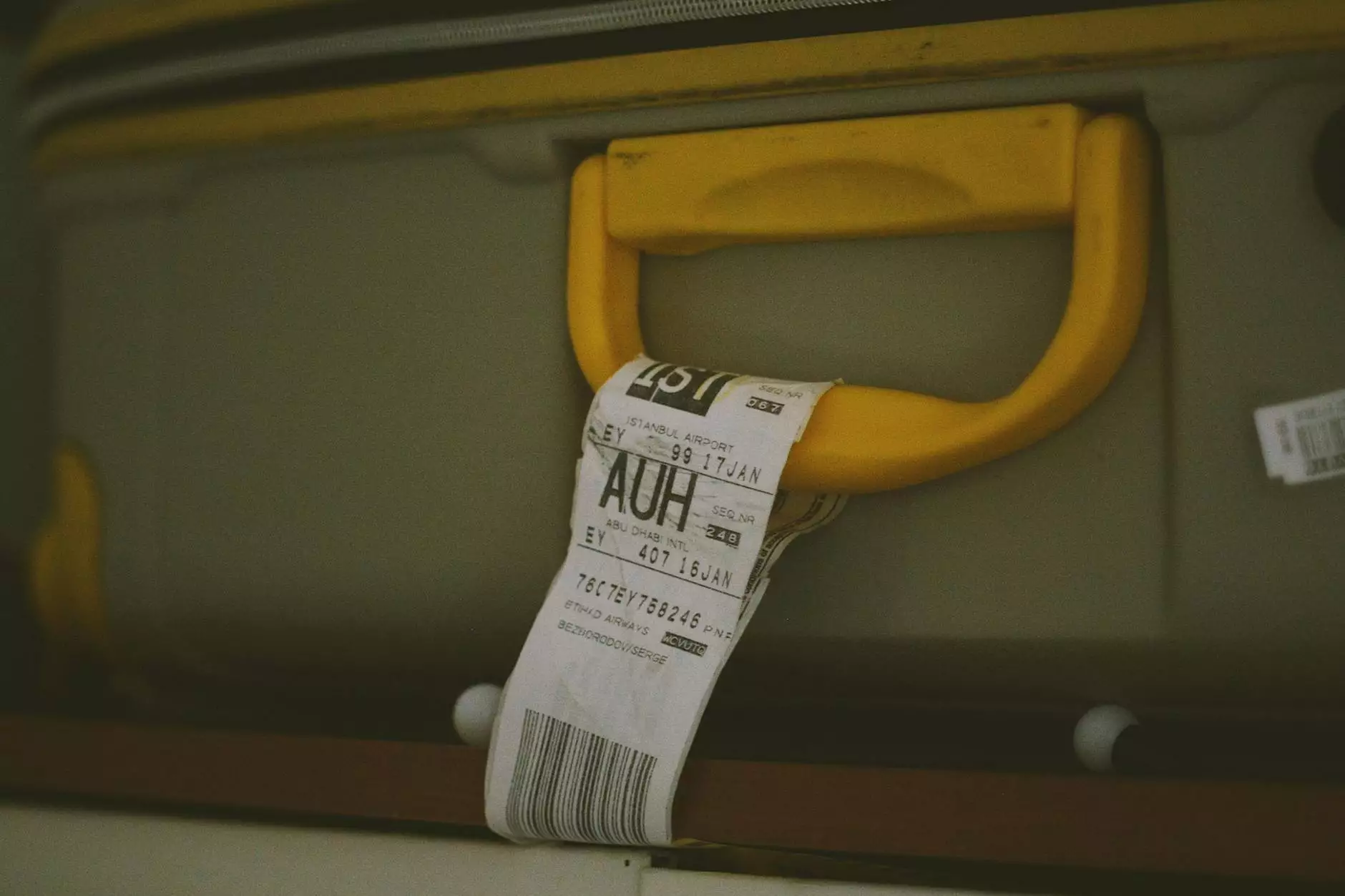

Where to Buy Quality Engine Fuel Pumps

For sourcing high-quality engine fuel pumps, look no further than client-diesel.com. This reputable supplier offers a wide variety of diesel engine parts, including reliable fuel pumps that meet stringent quality standards. Purchasing from established suppliers ensures that you receive a product that not only fits your engine specifications but also upholds high performance and durability.

Client Diesel: A Trusted Supplier

Client Diesel prides itself on being a leading provider in diesel engine parts and spare parts suppliers. Their extensive inventory includes:

- High-pressure engine fuel pumps

- Fuel pump repair kits

- Fuel filters and other accessories

By choosing products from client-diesel.com, you can ensure the performance and reliability of your diesel engine, ultimately leading to decreased downtimes and increased productivity.

Conclusion

In summary, engine fuel pumps are indispensable components that directly influence the performance and efficiency of diesel engines. Regular maintenance, timely updates, and purchasing quality products from trusted suppliers like client-diesel.com will help maintain your engine’s optimal performance. Understanding the functionality, types, and signs of failure of fuel pumps equips you with valuable knowledge that can save you time, money, and hassle in the long run.